Main menu:

PIPELINES

Pipelines

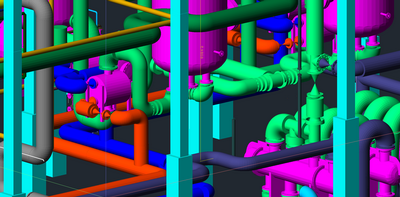

are an essential part of any industrial installation. Their design is subject to a number of regulations and standards. As pressure equipment, depending on the operating parameters are covered by the technical supervision of the respective state units. All these factors cause pipeline design requires some experience, relevant tools and knowledge of regulations and standards. Inter-Raf has documented thousands of pipelines in various fields over a 10-year period media as well as various parameters of work. We have extensive experiencein design of both simple

pipelines for low parameters (for low pressure steam, nitrogen, air, water, etc.) through pipelines for liquid and gaseous fuels, process gases (including hydrogen) up to power pipelines of the highest parameters used to transfer fresh steam, connecting boilers with turbogenerators. Each of these projects requires a different approach due to the specifics of pipeline

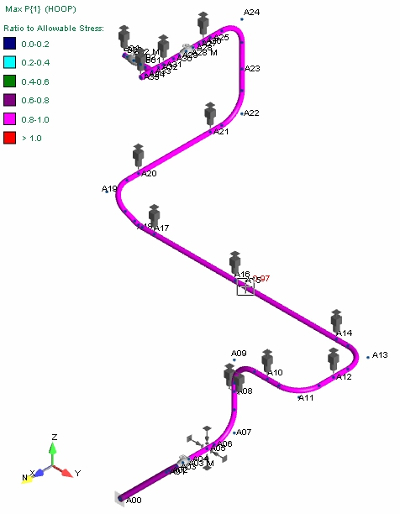

behavior in different job parameters. Inter-Raf offers its customers complete documentation of pipelines (3D models, 2D plans, isometric drawings, material lists) and all kinds of technical calculations (flow models, strength

calculations, stress analysis for elevated temperatures especially including pipelines operating in creep conditions). We offer selection or design of fasteners, supports, compensators, pipelines, insulation and

corrosion protection projects. Due to the extensive

design experience in this field, we can undertake virtually any task related to

technological pipelines. The documentation is handled by us in the Notified

Body or the Technical Inspection Office so the customer receives a ready

product that can be sent directly to the customer.

Reconstruction of the Cooling Water System.

Reconstruction of the Cooling Water System.As part of this task, Inter-Raf has designed modernization of three cooling water installations that cool and send water to the production departments. The scope of the project included the design of a completely new collector system at the cooling water pump station, design of new pipelines to supply water to the various departments. As additional elements on the pipeline, valve and instrumentation wells (for pressure parts) and wells for return water. In other disciplines, Inter-Raf has upgraded the DCS system with the provision of reserved fiber optic lines for connection to the Central Control Room. In addition, existing buildings on cooling water installation have been redesigned to install new medium and low voltage switchgear units equipped with ventilation and air conditioning.

The Synthetic Fuels Production Plant pipelines.

Inter-Raf has completed the documentation of the

construction of a Synthetic Fuel Production Plant with several hundred

pipelines with different parameters. Due to the small amount of space and high

operating temperatures, the pipeline section of the reactor section has a

complicated construction. The design of these pipelines required the expansion

of the expansion joints as natural compensations would be too large. An

additional challenge was the working parameters - these pipelines operate at a

high temperature of 350 degrees Celsius at a pressure of up to 25 bar, while in

the regeneration cycle the material from which they are already built falls

into the metal creep range. To meet this challenge, our specialists carried out

structural design checks to ensure that suitable pipe materials, compensators,

fittings and fittings were selected. As part of the design work, all pipelines

of the highest quality (PED category III) have been approved by our office in

the Notified Body UDT Cert.

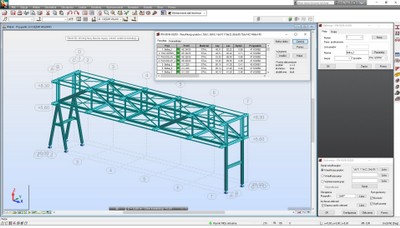

Pipelines in the tank farm 4 x 9600 m3

As part of this task Inter-Raf has completed the documentation of the construction of fuel collectors for storage tanks. Because of the large diameters, these pipes require a sufficient amount of fastening and support. In addition, electrically operated valves, service platforms and pipeline pressure protection were designed. As part of the design work, the Inter-Raf office has made documentation in the fields of: technology, mechanical, construction and construction, electricity, instrumentation, water and sewerage and documentation for pipelines.

Development of Biofuel Production Plant.

As part of this task Inter-Raf has completed the

documentation of pipelines combining technological equipment such as reactors,

columns, heat exchangers. As an interesting component of the installation

stainless steel piping additionally internally coated with plastic layer due to

very strong corrosive properties of some media can be mentioned. When designing

this type of pipeline, it is necessary to keep high precision in the inventory

of the existing condition because coated pipe sections are manufacture on size.

They are join by flange and correction of length is limited. As part of the

design work, the Inter-Raf has made documentation in the following disciplines:

technology, mechanical, construction, electrical, instrumentation and

documentation for pipelines. A documentation for building permit was made.