Main menu:

PRESSURE VESSELS

Inter-Raf team has design hundreds of different types of pressure equipment for a variety of technological processes over many years. Various types of materials were used - starting with the simplest carbon steel and ending with stainless and heat resistant steels - in several cases also coated with anti-corrosion coatings. At the same time, our company has accumulated a wealth of experience that allows us to undertake the most difficult design tasks for pressure equipment. Below we present some examples of implementation in this field.

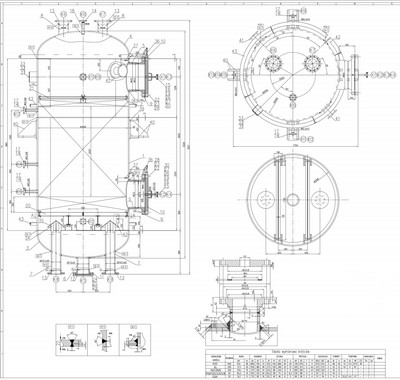

Process reactor for modifying the process gas stream on a catalyst bed. This unit operates in two different modes - the process mode is characterized by a pressure up to a maximum of 25 bar and a temperature of up to 350 degrees Celsius, while the bed regeneration mode is carried out at a pressure of 6 bar and a temperature of 530 degrees Celsius. Such a range of operating modes forced use of special materials that are not often used for the construction of such apparatus. Inside there are grate for catalyst maintenance and special constructions at the ends of the nozzle preventing of catalyst residue removal with the process stream. The high working temperature has forced the use of pawl construction with special insulating spacers to prevent temperature transfer to the bearing structure and thus to weaken it. As part of the order Inter-Raf completed the technological and construction calculations and completed the detailed and surveillance documentation.

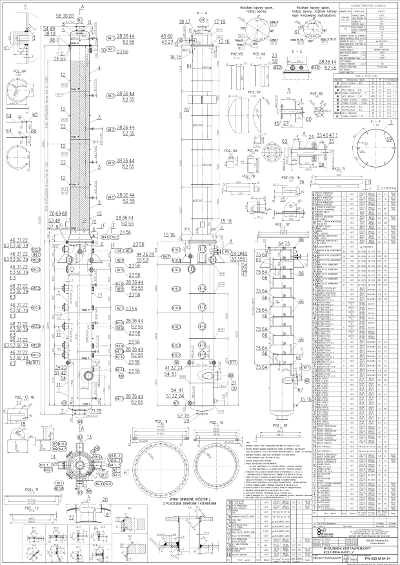

A scrubber for rinsing gasoline vapors at the fuel terminal. The flow rate of this apparatus is 300 Nm3/h and the solutions used in the flushing bed in combination with a specially selected washing liquid and demister resulted in a purge level of approx. 98%.

In the scope of commissioned work, Inter-Raf has performed the technological calculations of the scrubber, the design and the supervision of the apparatus and the connection to existing installations in the mechanical, electrical and instrumentation.

Hydrocarbons distillation columns system. The columns

allow fractionation of the hydrocarbon stream into gasoline, oils, light

fractions and separation of the heavy phase.

As part of the order, Inter-Raf has performed

technological calculations, construction and detailed and surveillance designs.

Methanol distillation column. Its task is to separate methanol to the maximum from the stream consisting of biofuel and glycerin. The high efficiency of this apparatus ensured the purity of the product passed to the rest of the production plant. As part of the order, Inter-raf has performed structural calculations and detailed designs.