Main menu:

RELOADING TERMINALS

In the meaning of the state regulations on Technical Transport Supervision, the loading and unloading arms are only a small part of the reloading installations. Usually it is understood by the arm or hose used to load or unload medium. However mostly the loading/unloading devices are grouped in rail or car tank multi-terminal connected by a pipeline system with pumping stations and storage tanks.

Inter-Raf has wide experience in design of both small stations as well as large loading and unloading terminals for car tankers or railcars. Any documentation of the L/U device is approved by us in the Technical Transport Inspection. We may offer a very wide range of services to our customers related to loading or unloading of various substances. In our portfolio we have realized the systems of handling liquid fuels,

liquefied gases, chemicals, asphalt and loose materials. We make full documentation of L/U terminals including civil, construction and road or rail discipline. We also offer flow analyzes of existing loading or unloading fronts related to their modernization or improvement of operating parameters.

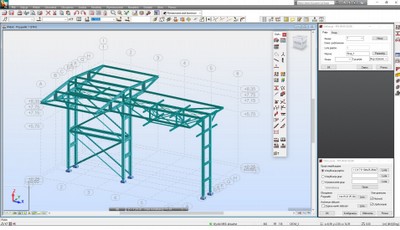

Crude oil unloading terminal.

Crude oil unloading terminal.As part of this task, Inter-Raf has completed the documentation of crude oil terminal modernization and approved it in Technical Transport Supervision. As part of the design work, Inter-Raf has made documentation in following disciplines: technology, mechanical, construction, electrical, instrumentation.

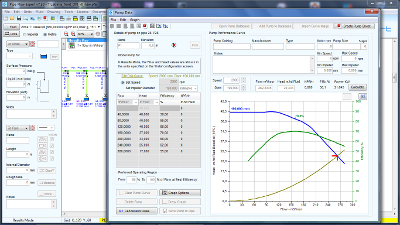

Car tank bottom fuel loading terminal

Inter-Raf has completed the

documentation of car tanks fuel bottom loading terminal modernization and approved

it in Technical Transport Supervision. Before the modernization it was the top loading

terminal. The aim of the project was to change the method of loading and the

possibility of pouring into five chambers simultaneously and collecting vapors.

As part of the modernization, replacement of loading pumps and pipelines was

also designed. Pouring into chambers takes place with online addition of fuel

additives. As part of the design work, Inter-Raf has made documentation in following

disciplines: technology, mechanical, construction, electrical, instrumentation

and building design to obtain a building permit.

Liquefied sulfur dioxide railcars top unloading station.

Liquefied sulfur dioxide railcars top unloading station.As part of this task Inter-Raf has completed the documentation of liquefied sulfur dioxide unloading station modernization and approved it in Technical Transport Supervision. The railway siding was rebuilt. The unloading takes place in the process of extrusion of sulfur dioxide by compressed air. As part of the design work, Inter-Raf has made documentation in following disciplines: technology, mechanical, construction, electrical, instrumentation, water and sewage, railway and documentation for pipelines, L/U devices. A building permit was obtained by Inter-Raf.

Biofuel railway loading terminal.

As part of this task Inter-Raf has completed the documentation of the biofuel railway loading terminal modernization and approved it in Technical Transport Supervision. As part of the design work, Inter-Raf has made documentation in following disciplines: technology, mechanical, construction, electrical, instrumentation, water and sewage, as well as documentation for pipelines, L/U devices. A building permit was obtained by Inter-Raf.