Main menu:

STORAGE TANKS

Inter-Raf team specialize in storage tanks designing of various sizes and types. We offer design documentation of low pressure vertical storage tanks in accordance with the EN-14015 with single shell or with addition cover shell, with heavy floating roofs, with light floating covers and “umbrella” type roof. Tanks can be heated by internal or external coils or heaters in the form of heating pads and equipped with mechanical or hydrodynamic mixers. We have implementation experience for tanks realization of this type with capacities from 50 m3 to 10.000 m3 on various types of media - fuels, oils, water, chemicals. Members of the team have experience in designing such tanks with a capacity of up to 50,000 m3. If necessary we can also offer documentation of tanks according to API650 and EN 19914.

The second group of tanks we can offer our customers are horizontal and vertical pressure tanks according to EN 13445. We have experience in designing such devices in capacities up to 300 m3. Tanks of this type are often equipped with mixers and immersion heaters or electrical heating. In addition, we offer selection of valves and fittings, which should be installed on the tank. Particular attention should be paid to the overflow and overpressure protection devices of tanks. Our designers select the appropriate breathing valves or safety valves for your application, taking into account the specificity of the process and external factors such as fire. Designing a tank equipped with all security devices Inter- Raf takes over responsibility for the safe operation of the tank by removing the risk of improperly protecting the tank from the customer.

We present below some selected realizations of storage and technological tanks.

Inter-Raf made documentation of four diesel oil storage tanks with a capacity of 10000 m3 each. Cylindrical, vertical, with curtain wall, equipped with umbrella type light roof and internal light floating cover according to PN-EN 14015. Tanks were designed in a standard suitable for storage of Class I fire hazard fluid. It means that tanks have the sprinkler system of a roof, shell and a curtain wall and foam system. For fire protection purposes, four semi-fixed fire stations are provided with automatically controlled water valves for the sprinkler system. Within the scope of the task documentation was made in following disciplines: technology, construction, road, bridge, piping, water and sewage, electrical, instrumentation and telecommunication. Inter-Raf has also provided equipment and fittings specifications, explosion hazard documentation, and HAZOP Hazard Analysis. The project also included an environmental impact statement, an environmental decision and a building permit.

Inter-Raf made documentation of three storage tanks for various light hydrocarbon fractions of 1000m3 each modernization located in a common concrete anti-fouling tray. Cylindrical tanks, vertical, equipped with heavy fixed roof and internal light floating cover according to PN-EN 14015. Tanks were designed in a standard suitable for storage of Class I / II or III fire hazards fluid. This combination of storage functions means non compliance with the applicable regulations for the storage of liquid fuels. Inter-Raf applied to the National Fire Brigade Headquarters for permission to work in such a configuration using additional fire protection and obtained such consent. Tanks have a roof and shell sprinkler system and an foam installation. For fire protection purposes, a semi-fixed distribution station is provided with automatic controlled water valves for the sprinkler system and fire foam supply connections. Within the scope of the task documentation was made in following disciplines: technology, construction, road, bridge, piping, water and sewage, electrical, instrumentation and telecommunication. Inter-Raf has also provided equipment and fittings specifications, explosion hazard documentation, and HAZOP Hazard Analysis. The project also included an environmental impact statement, an environmental decision and a building permit.

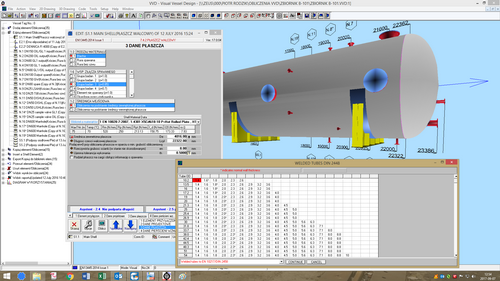

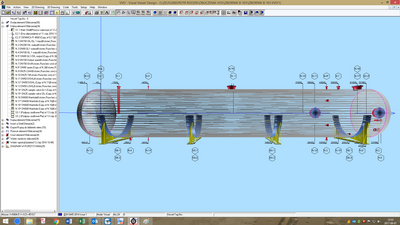

Technological tank 77 m3 for neutralization of used caustic

soda by perhydrol. Horizontal tank, designed in accordance with EN 13445.

Within the scope of the task, documentation was made in the fields of:

technological, construction, steel structures, piping, water and sewage,

electrical and automation. The tank is part of the waste liquor neutralization

plant, which was designed entirely by our company.

Technological tank for biofuel and glycerine sentimentation with a capacity of 300m3. Horizontal tank, designed in accordance with EN 13445. As part of the task, documentation was carried out in the following disciplines: technology, construction, piping, water and sewage, electricity, instrumentation. As part of the order Inter-Raf also performed a project for UDT.

Inter-Raf made documentation of four vegetable oil

storage tanks and a biodiesel capacity of 2 x 1900m3 and 2x770m3. Cylindrical vertical

tanks, inside a common concrete anti-slip tray was designed, equipped with

heavy fixed roof in accordance with PN-EN 14015. Along with the park tanks Inter-Raf

designed pumping station, biofuels loading station for car tanks and complete

piping. Tanks and piping are electrically heated by heating cables. As part of

the task, documentation was made in the following disciplines: technology,

construction, road construction, piping, water and sewage, electrical, instrumentation

and telecommunication. Inter-Raf has also provided equipment and fittings

specifications, explosion hazard documentation, and HAZOP Hazard Analysis. The

project also included an environmental impact statement, an environmental

decision and a building permit.