Main menu:

HEAT EXCHANGERS

Heat exchanger is one of the most used appliances on most production plants. Our company providing comprehensive project management services offers our clients full documentation on this issue. We design tube heat exchangers in various configurations according TEMA standards. In case of a new device design, we usually make thermal calculations for the streams in the exchanger by selecting the correct type of device. The exchanger is then calculated to the appropriate pressure equipment regulations - usually the EN 13445 standard, but we also offer strength calculations in most recognized world standards (ASME, EN13480, EN1591, PD5500, AD2000). We also make documentation according to the PED and the UDT, which may be approved by us on behalf of the Client.

In case of improper operation of existing exchanger, we offer you thermal and strength calculation and presentation of proposals and solutions improving the functioning of the device.

We also make thermal calculations for plate and spiral heat exchangers and we choose solutions of manufacturers of this type of equipment. During ten years of operation Inter-Raf has designed many different types of heat exchangers that are constantly working on installations. The accumulated experience allows us to offer you high quality design documentation for this type of pressure equipment. Below you will find some selected implementations in the field of heat exchangers.

Phenol vapor condenser.

As part of this task Inter-Raf has completed the documentation of the modernization of the phenol condensation installation, the main goal of which was to reduce consumption of LP steam by using process stream heat. An additional heat exchanger - a BGS type exchanger has been designed. As part of the modernization of this node, regulators and connections to existing installations were made. The building was made on an existing rack, which was calculated for durability due to increased load. As part of the design work, the Inter-Raf has made documentation in following disciplines: technology, mechanical, construction, electrical, instrumentation.

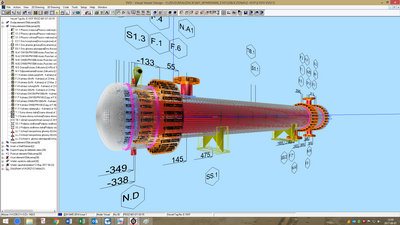

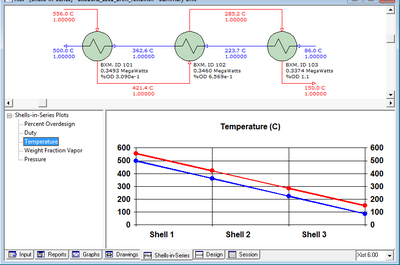

Flue gas cross heat exchanger.

Inter-Raf has designed a set of three heat exchangers

working in series that have cross-flow heat exchange of two gas streams. This

is a very interesting and difficult application due to high working

temperatures up to 550 degrees Celsius and minimum pressure drop required. The

challenge was also a pipeline connection between heat exchangers that had to be

specially compensated for the high temperatures. Exactly accurate thermal

calculations and properly designed machine construction result in proper

operation of the entire node despite extremely difficult working conditions.

Process gas cooler.

As part of this task, Inter-Raf has designed the

modernization of the process gas cooling plant, the main goal of which was to

limit the discharge of condensate contaminated with ammonia into sewage. As

part of the modernization of the node, regulators and connections to existing

installations were made. The building was made on an existing rack, which was calculated

for durability because of the load increase and properly reinforced. As part of

the design work, Inter-Raf has made documentation in following disciplines:

technology, mechanical, construction and construction, electrical, instrumentation.

Methanol condensers.

As part of this task, Inter-Raf has completed the

documentation of the modernization of the methanol condensation node. The

existing heat exchanger system was not working at sufficient efficiency, which

was manifested by increase of methanol emissions to the plant's vapor pendulum.

An additional heat exchanger was created - the condenser, while the existing

exchangers after the changeover to the technological system were used for other

purposes. As part of the modernization of the node, regulators and connections

to the existing equipment were made. The exchanger was built in an existing

production building, which was calculated for durability due to increased load.

As part of the design work, the Inter-Raf has made documentation in following disciplines:

technology, mechanical, construction, electrical, instrumentation.